Home > Products > IDEC Range Products > Safety Components > Safety Interlock

The Safety Interlock is a vital component in industrial safety systems, designed to prevent accidental or hazardous operations by ensuring that machinery and equipment are only used under safe conditions. By integrating Safety Interlocks into industrial setups, businesses can significantly reduce the risk of accidents and ensure that machinery operates only when it is safe to do so, thereby safeguarding both personnel and equipment.

Safety Interlocks play a crucial role in enforcing safety protocols by locking out or controlling machinery until specific safety conditions are met. These devices ensure that machines cannot be operated unless all safety measures are in place, such as safety guards, emergency stops, or maintenance doors being properly closed. This functionality not only protects operators from potential harm but also helps in maintaining the integrity of the equipment, leading to safer and more efficient industrial operations.

Orbital Mekatronik Systems Pvt. Ltd. is a leading manufacturer, supplier, and exporter of high-quality Safety Interlocks. We are renowned for our commitment to reliability, precision, and innovation in industrial safety solutions. Our Safety Interlocks are engineered to meet the highest standards of safety and performance, reflecting our dedication to providing top-notch safety solutions that enhance industrial safety and operational efficiency.

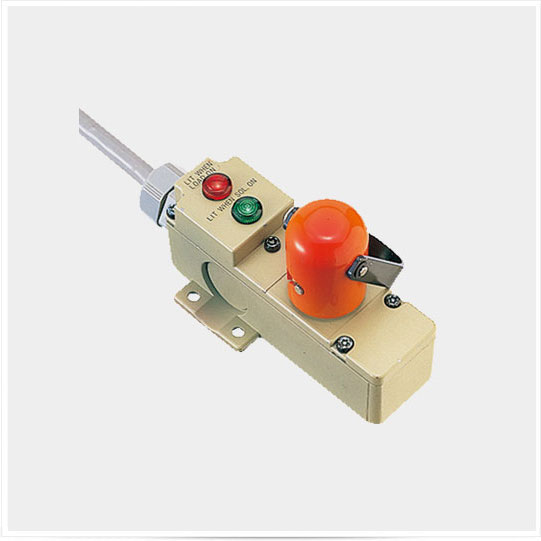

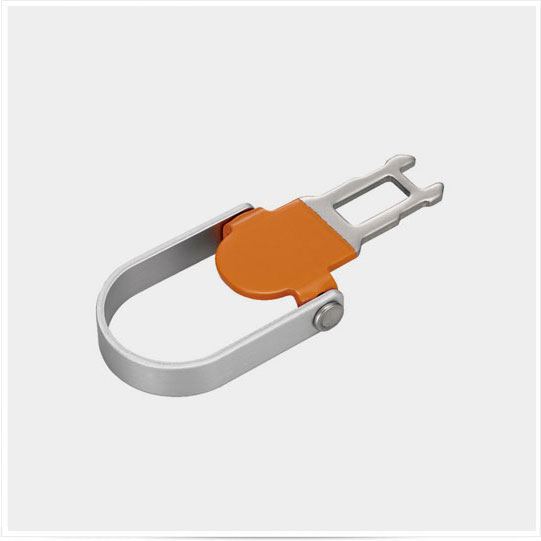

Explore our range of Safety Interlocks to find the perfect fit for your needs:

When choosing the right Safety Interlock, it’s essential to consider the specific features and types that align with your application’s needs. HS1T Heavy Duty Locking is ideal for high-stress environments requiring robust protection. For smaller or more compact applications, HS6B Subminiature and HS6E Subminiature Locking offer a space-saving solution with reliable safety features. HS5L Miniature Locking and HS5D Miniature are suitable for applications needing a smaller profile but still demanding secure locking. HS5E-K Miniature Locking and HS1L Full-size Locking are designed for general industrial use where more substantial protection is needed. HS1B, HS2B, HS1C, and HS1C-K Full-Size Locking provide enhanced safety for larger machinery and equipment. For high-performance needs, consider the HS1P Series and HS2P Series, while the HS3A Non-Contact RFID and HS7A-DMC or HS7A-DMP Non-Contact Magnetic offer advanced non-contact safety solutions. For door-related applications, HS5 Door Handle, HS5 Slide, and HS5 Slide Handle are practical choices. Finally, the HS5 Plug, HS5 Pado Lock, HS5E Series, and HS5B Series provide additional options for various safety and locking requirements. Matching the right Safety Interlock to your application ensures optimal safety, efficiency, and compliance with safety standards.

© 2024 Orbital Mekatronik Systems Pvt. Ltd. All rights reserved.

Designed by Vebiotic Web Solutions Marketing by Adinads